WHY WMS?

Warehouse Management System (WMS) is a key part of organization of logistic chain and it’s main purpose is to control movement of goods in the warehouse by monitoring and controlling logistic processes. A typical WMS functionality includes control of the reception, storage, picking and delivery. The ability of the system to control and optimize the flow of goods is based on the rules and logistical capabilities of the system to provide real-time information on the status and location of goods, storage availability, reception and delivery requirements.

DO YOU HAVE THESE PROBLEMS?

- You have trouble in distinction between similar looking items?

- You have significant loses and number of returns has increased because of the delivery of wrong items?

- You don’t know the exact state of stock due to frequent mistakes in delivery?

- You have goods with expiration date and it is important to you that you have an accurate picture of the entry, stock and dispatch of goods?

- Traceability of the goods delivered, at the level of the lot and the date of manufacture, are of the key importance in your business?

- You have constant problems with a lack of poor disposition or warehouse space?

- You need a real-time insight about the status and activities of the stock in the warehouse?

WHAT DO YOU GET WITH THE INTRODUCTION OF WMS SYSTEM?

- Faster flow of goods from receipt to loading orders

- Full traceability of goods throughout the storage cycle

- Output of goods by FEFO / FIFO principle

- Better use of storage space

- Increased accuracy in order picking, guided picking

- Better control and inventory management

- Greater efficiency and better control of workers in the warehouse

- Faster and more accurate stocktaking

WMS

Our WMS is an information technology warehouse management system (WMS). The system is flexible and tailored in accordance with the requirements and methods of operation of customer and in accordance with the modern logistics principles and rules. It is able to operate in conjunction with the ERP and TMS systems, as well as to operate independently in the event that it is necessary. The system itself was developed with the use of modern information technologies enabling modularity and flexibility.

SERVER SIDE

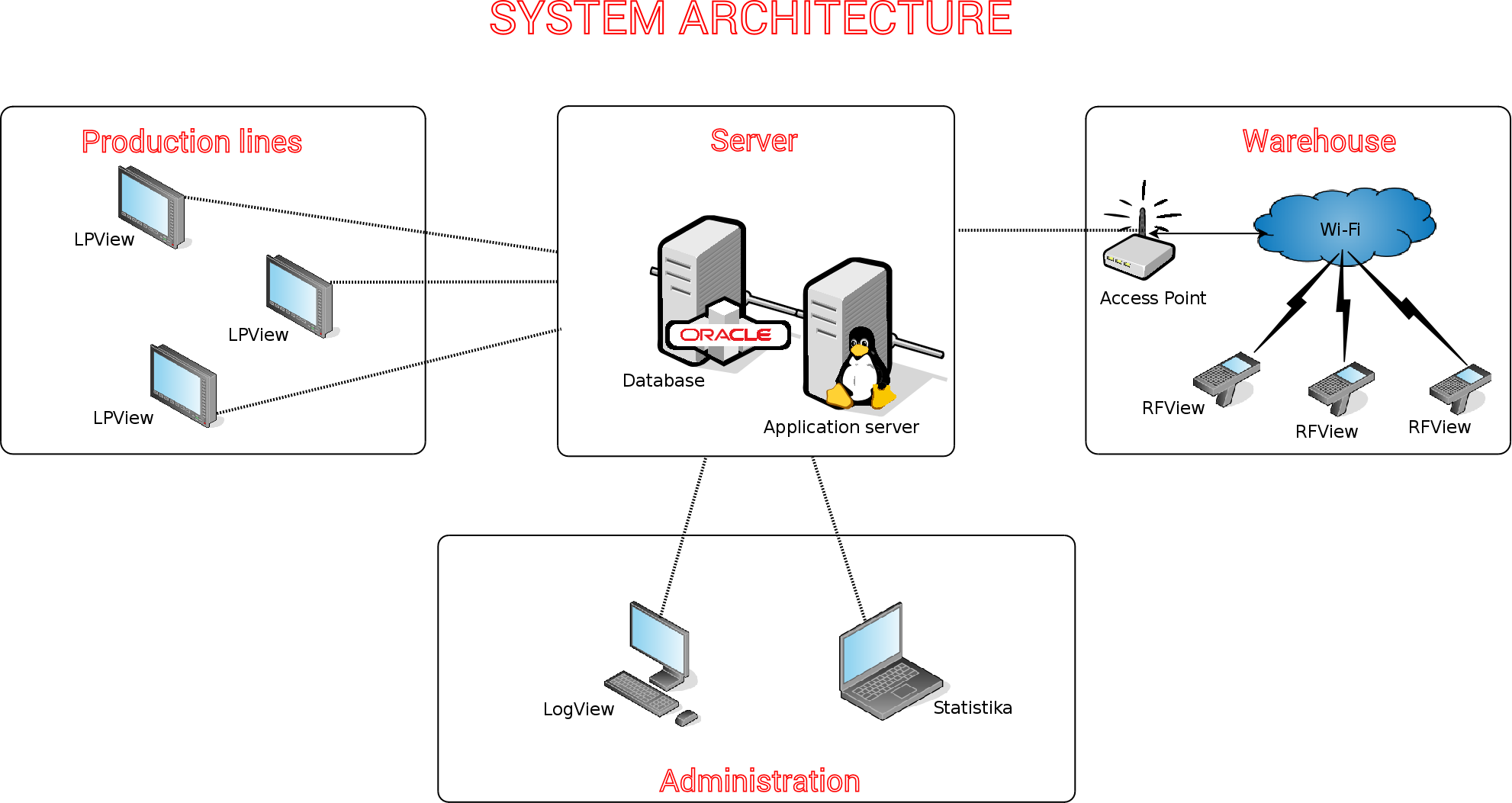

Our WMS is a server-side, modular, JavaEE application that helps you in your warehouse management. It’s tree layer architecture provides safe, fast and stable environment for system functionality and it represents the hearth of the system in which the whole business logic resides.

Mindful of the basic laws of logistics, our WMS offers you with the most modern solution for the management and control of your storage space, which is adaptable to all types of warehouses, regardless of storage capacity, the number of the employees, the quantity of trade goods or types of material. Our WMS, as a whole, provides all the information you need for daily operations and planning, both retroactively and in real-time, tends to use your storage space to the maximum, reducing the possibility of user error to the very minimum, thus enabling everyday financial savings and potential for constant growth and expansion.

Server:

- Oracle Linux

- Oracle Database (opciono PostgreSQL)

- Glassfish Application Server

HCOM – COMMUNICATION MODULE

Interface description

For the needs of real-time communication between WMS and other information systems we have developed communication interfaces which provide secure and fast data exchange. So far, we have successfully integrated interfaces with ERP systems such as SAP, Dynamics NAV, Wings, Pantheon, Aurasoft and ASW.

Purpose of HCOM interface is data exchange between remote systems over TCP/IP infrastructure (intranet or internet). Information between systems can be passed in any number of ways. Some of them include exchanging flat-files, using intermediate database, exchanging XML files or using web services.

Master data of articles, clients, suppliers, supply orders, sales orders, receipt confirmations, inventory adjustment for lost / found stock and comparison of stock supplies between systems are easily exchanged with minimal changes of Host (ERP) system. Beside communication with Host information system, HCOM interfaces supports data exchange between remote WMS systems.

Like other modules of our WMS package, HCOM interface is characterized by high level of configuration in order to fully meet clients expectations and needs.

CLIENT APPLICATIONS

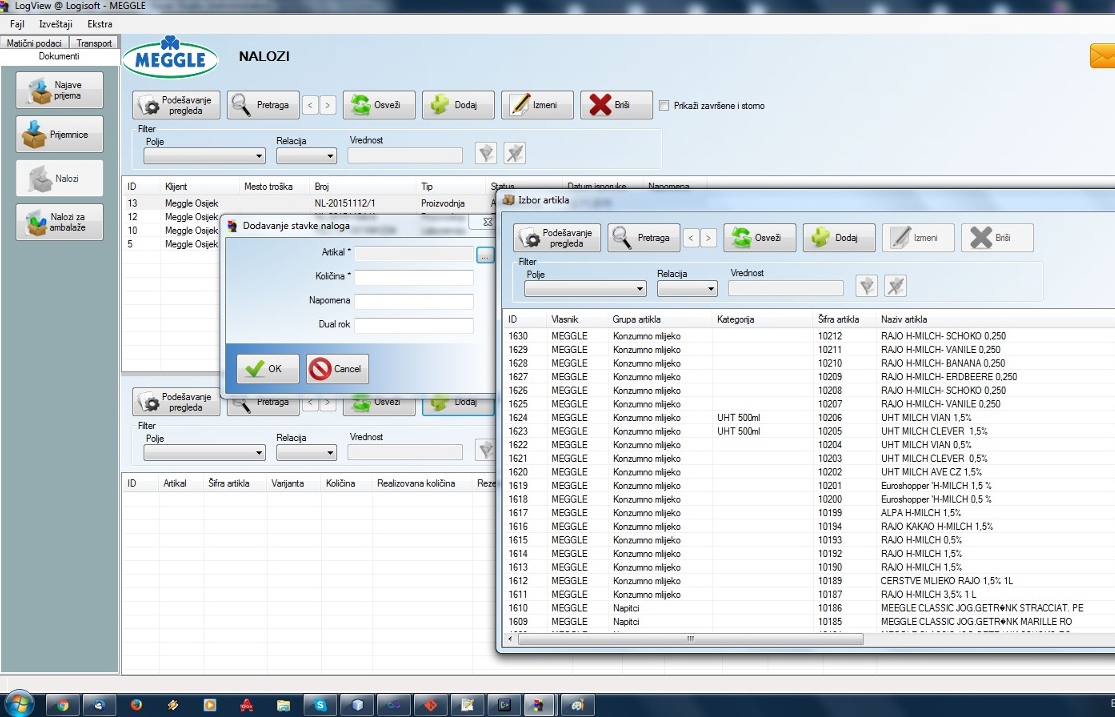

Log View

Application description

LogView application allows administrative control of entire WMS system. It is adjusted for all desktop and laptop computers, and gives fast, easy and safe management of master data, documents for entry , dispatch and transport of goods, control of entire warehouse, goods as well as warehouse structure and work force. It’s modularity

provides entire flexibility and control of user’s access to WMS system, while every user has possibility of creating his own working environment.

Functionality that basic package provides is possible to expand, depending on the work process of the warehouse and its needs.

Functionality provided in the basic package

- Management of master data (products, customers, vendors, drivers, vehicles, etc.)

- Control and printing of documents for entry and dispatch of goods (receipt and dispatch note)

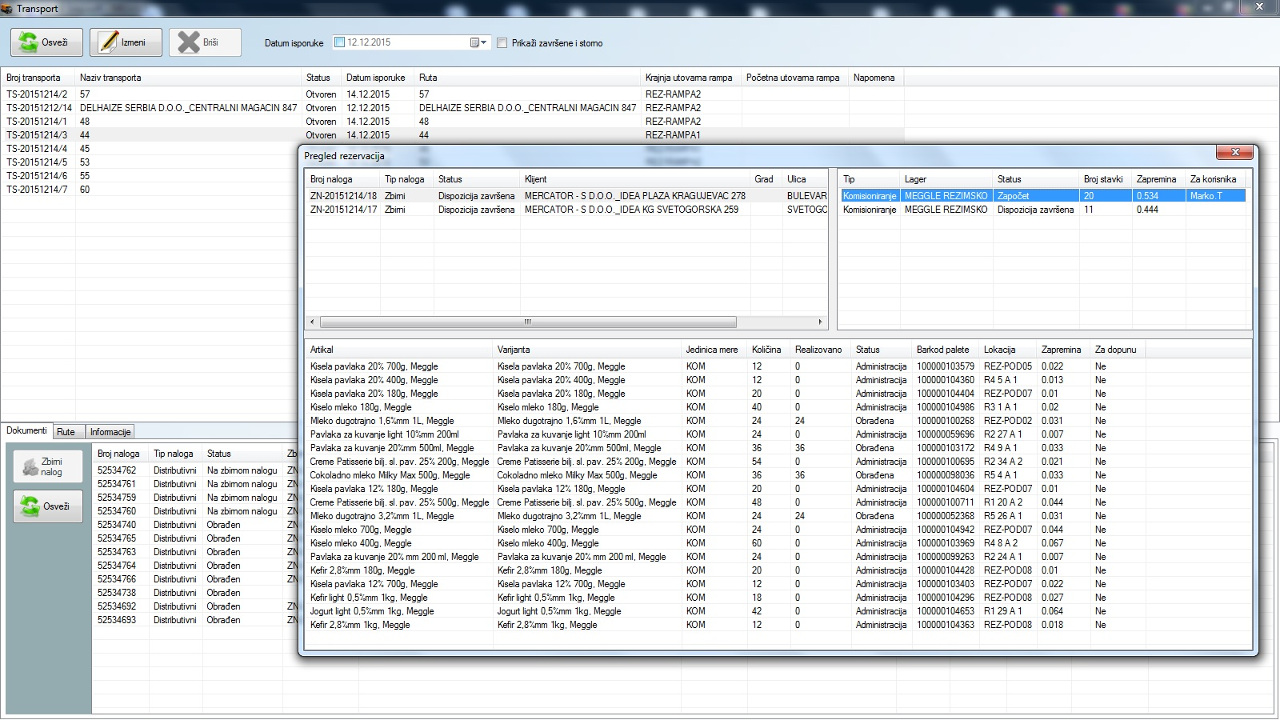

- Establishment, manipulation and transport control (basic TMS)

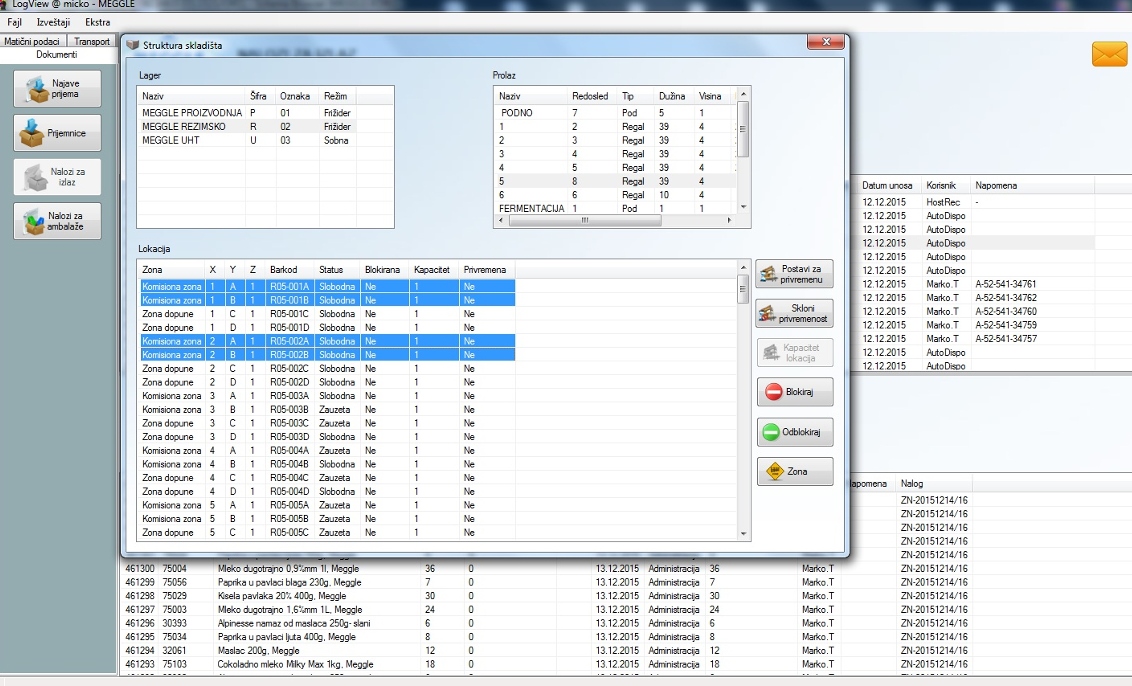

- Administration of the warehouse structure – blocking and releasing of pallet places, warehouse zoning

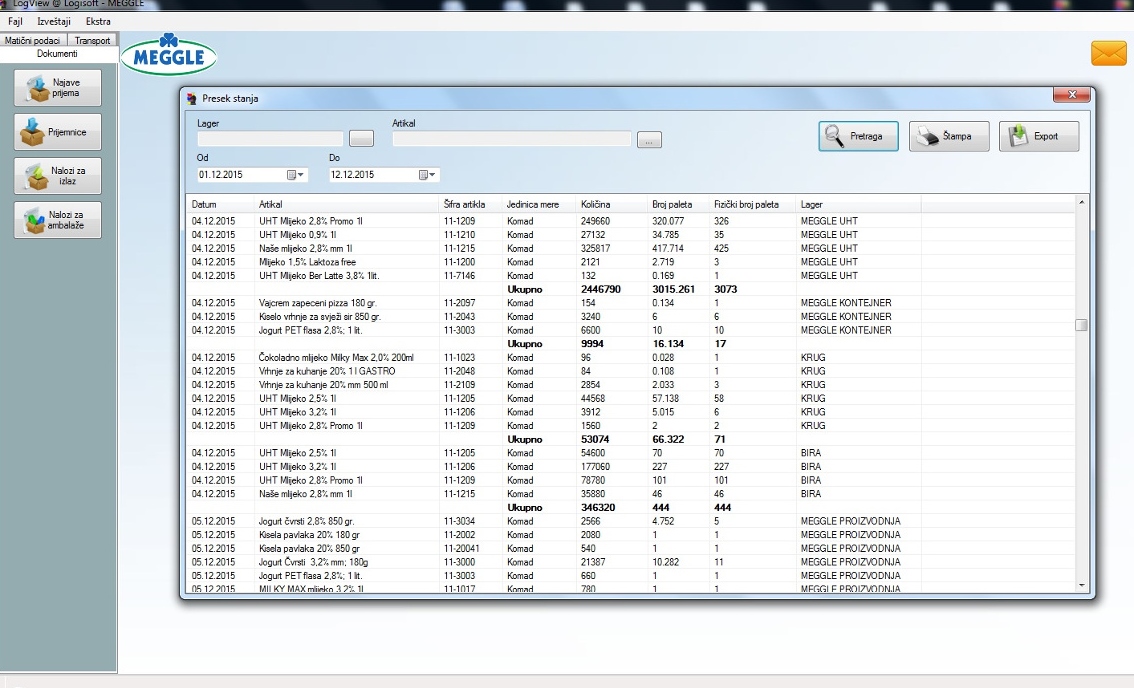

- Item tracking – retroactive review of inputs and outputs of an item in any given time period

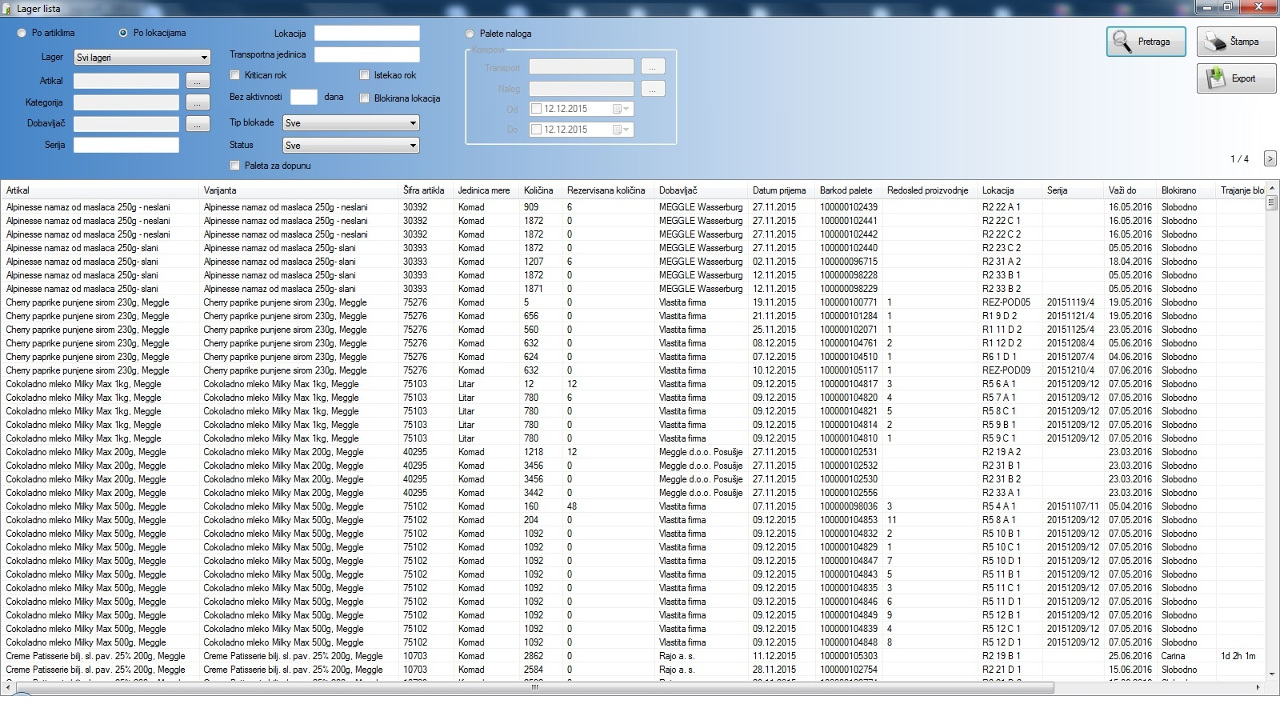

- Stock List – Review and administrative management of goods in stock

- Printing of new or existing barcode labels for operational work in the warehouse

- User administration and user access rights

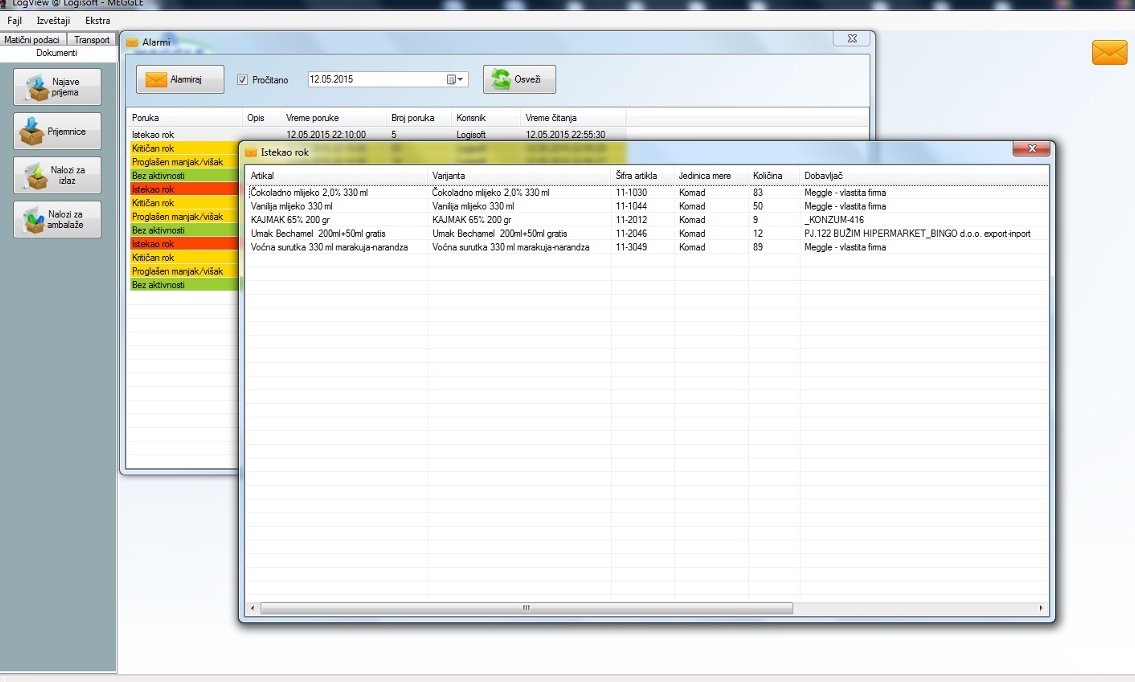

- System alerting and informing users about critical situations, alarming conditions of goods, etc.

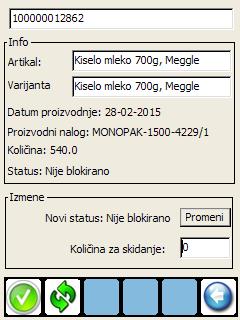

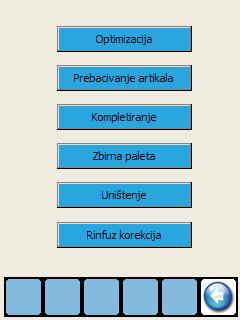

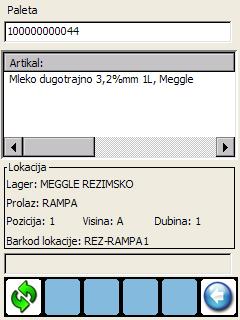

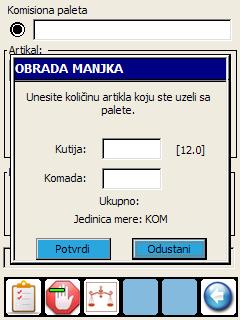

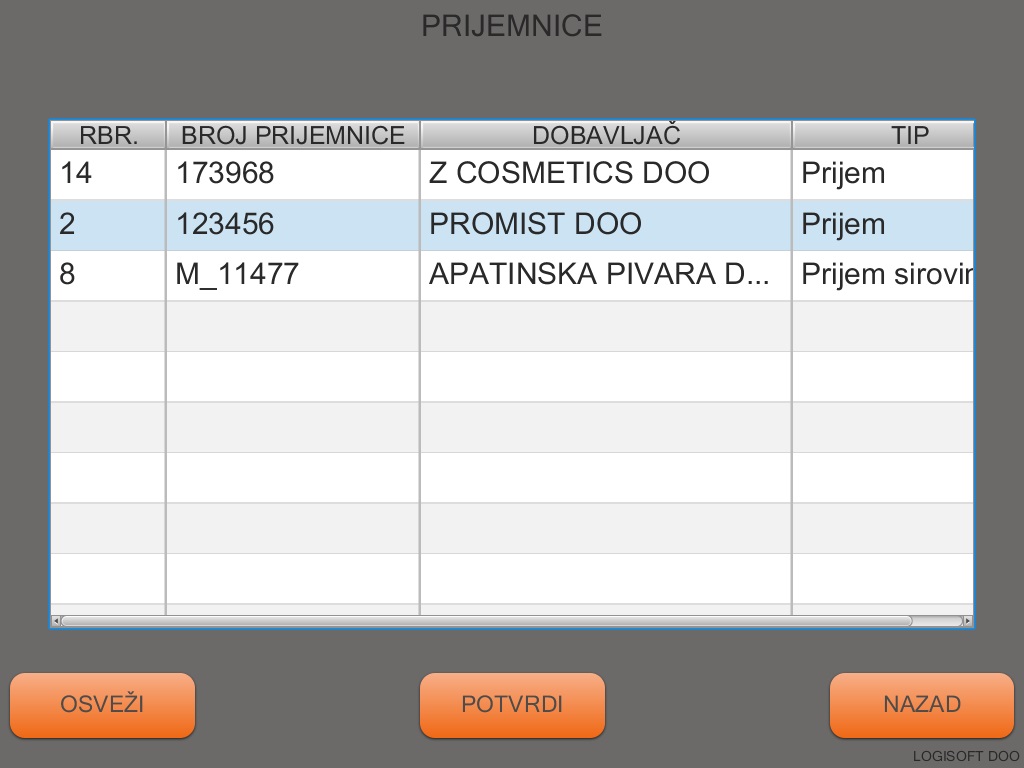

WMS RFView

Application description

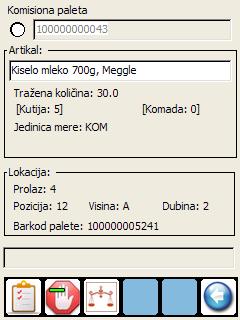

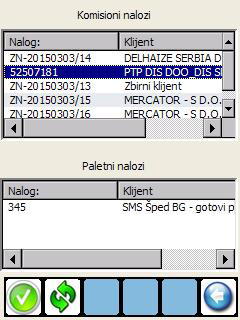

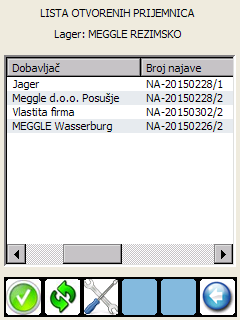

RFView application is customized for mobile computers with a scanner used in the warehouse at the operational level and allows easy and safe handling of materials in the business process. It was developed on the Windows CE platform and works on devices of all better known world manufacturers (Motorola, Datalogic, Honeywell ..). It is based on a client-server architecture which allows real-time communication between mobile computers and servers using a wireless connection (Wi-Fi).

The application is flexible and besides the basic package, it is possible to develop specific modules and functionality in accordance with the requirements and needs of the client.

Functionality provided in the basic package

- Receipt of goods in the warehouse from a ramp or from production plants

- Relocation of pallets around storage locations and predefined zones

- Reading weight barcodes for diffuse goods

- Handling of goods in the warehouse, transfer of goods from one pallet to the other and the creation of mixed pallets

- Processing commission orders (picking) guided by the system

- Control of loading of the goods of assigned transports

- Warehouse inventory, inventory at the possibility of a separate stock or single article

- The possibility of assigning of different levels of authorization and access to different users

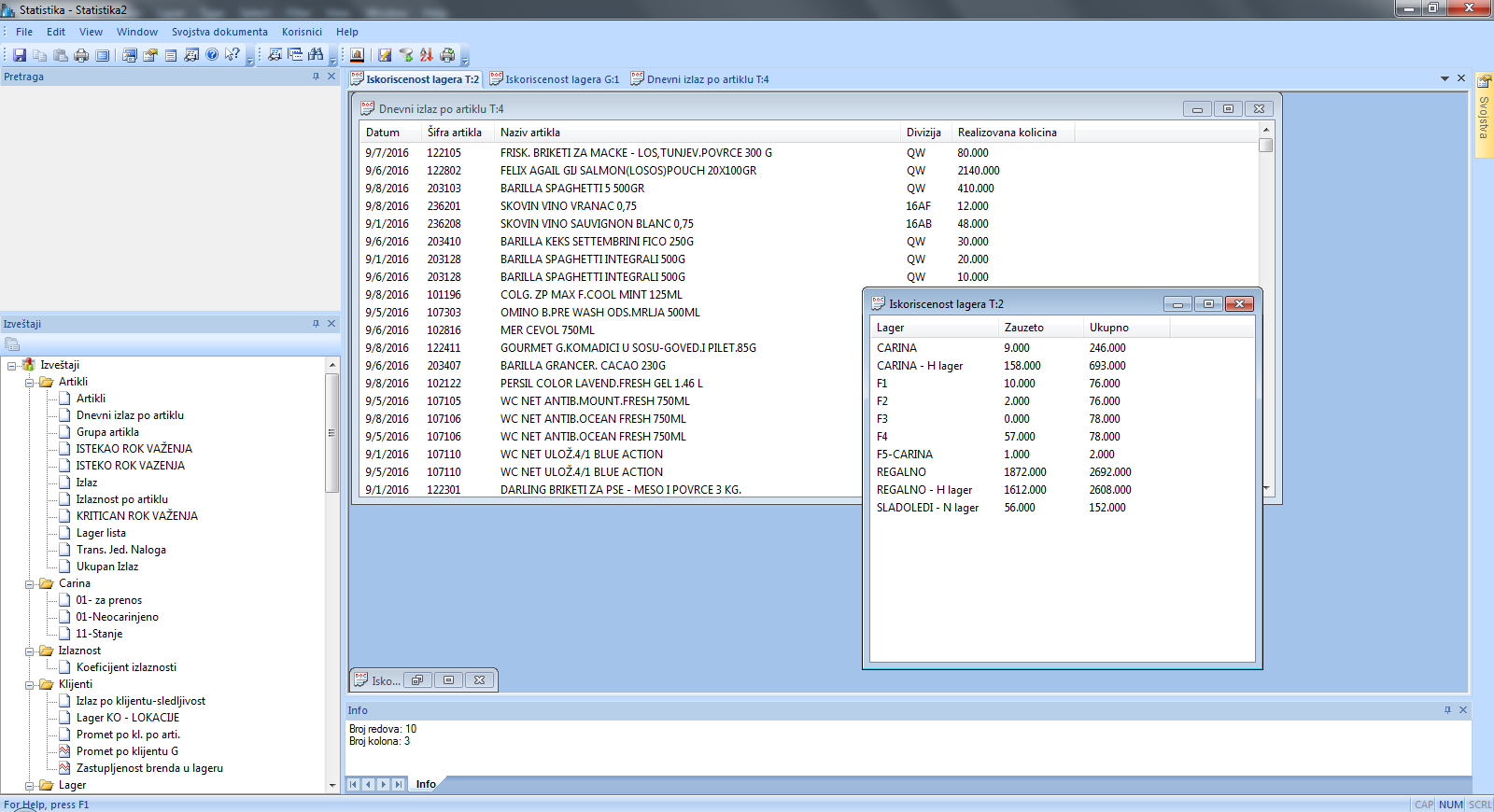

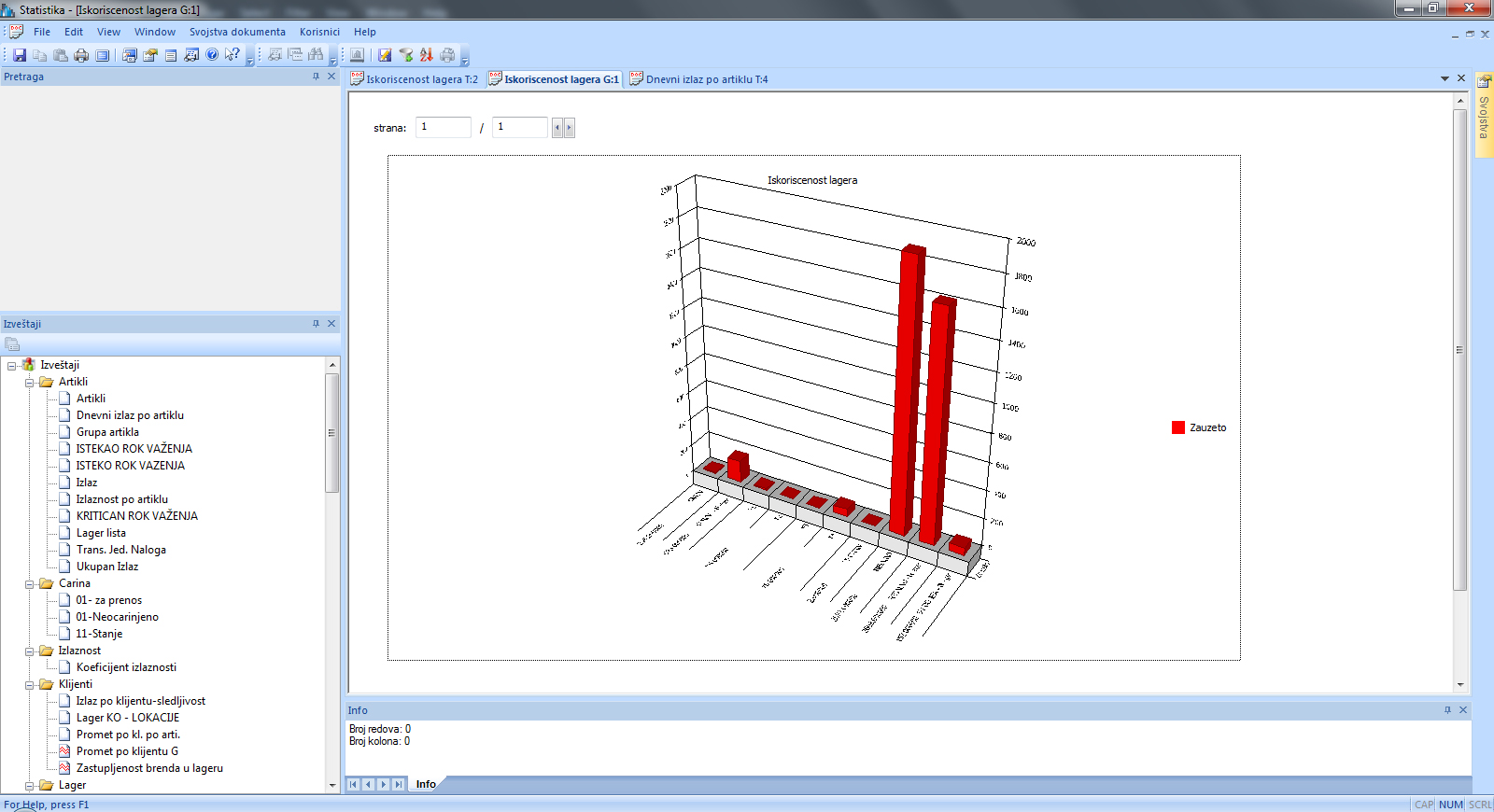

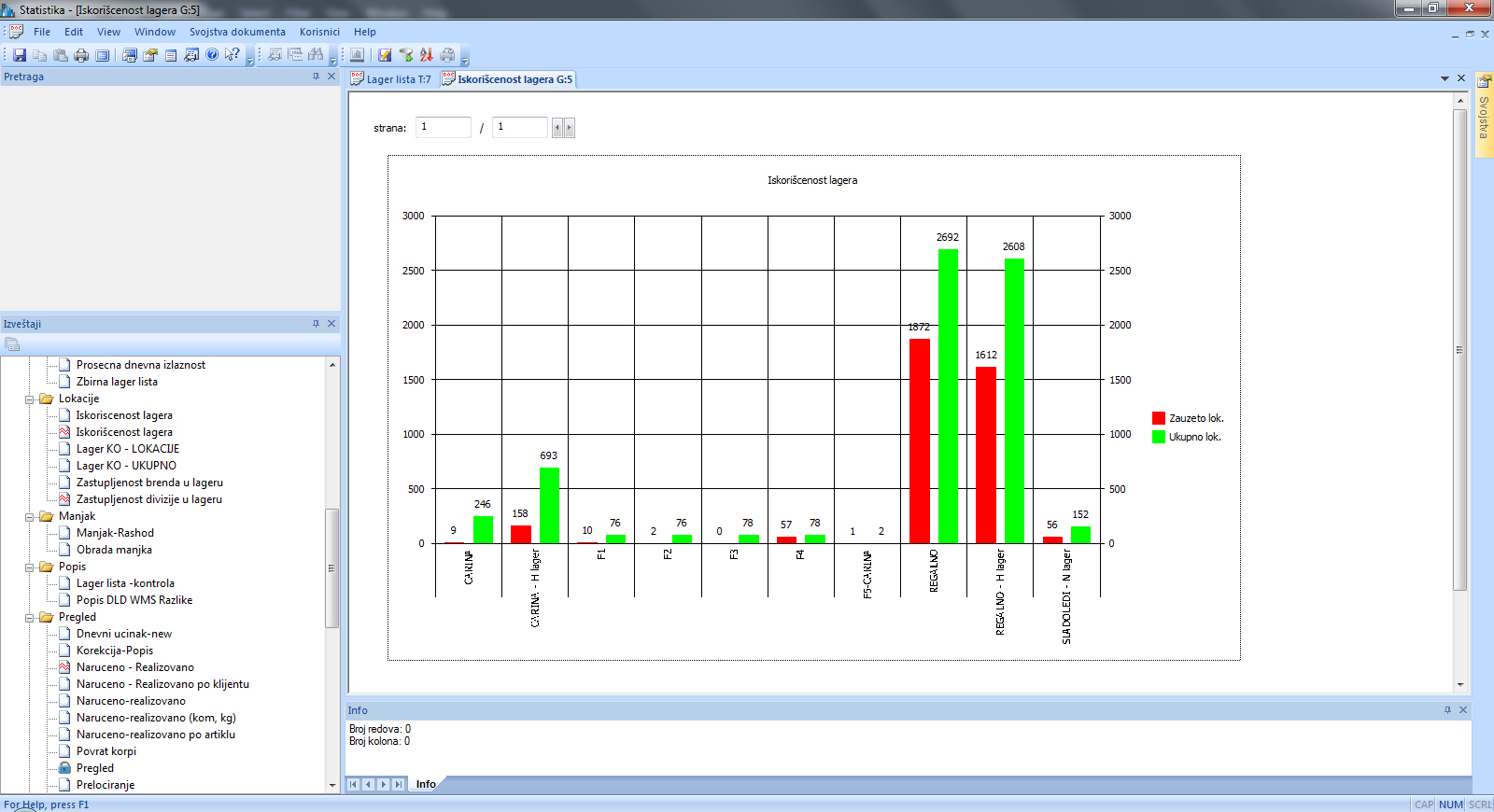

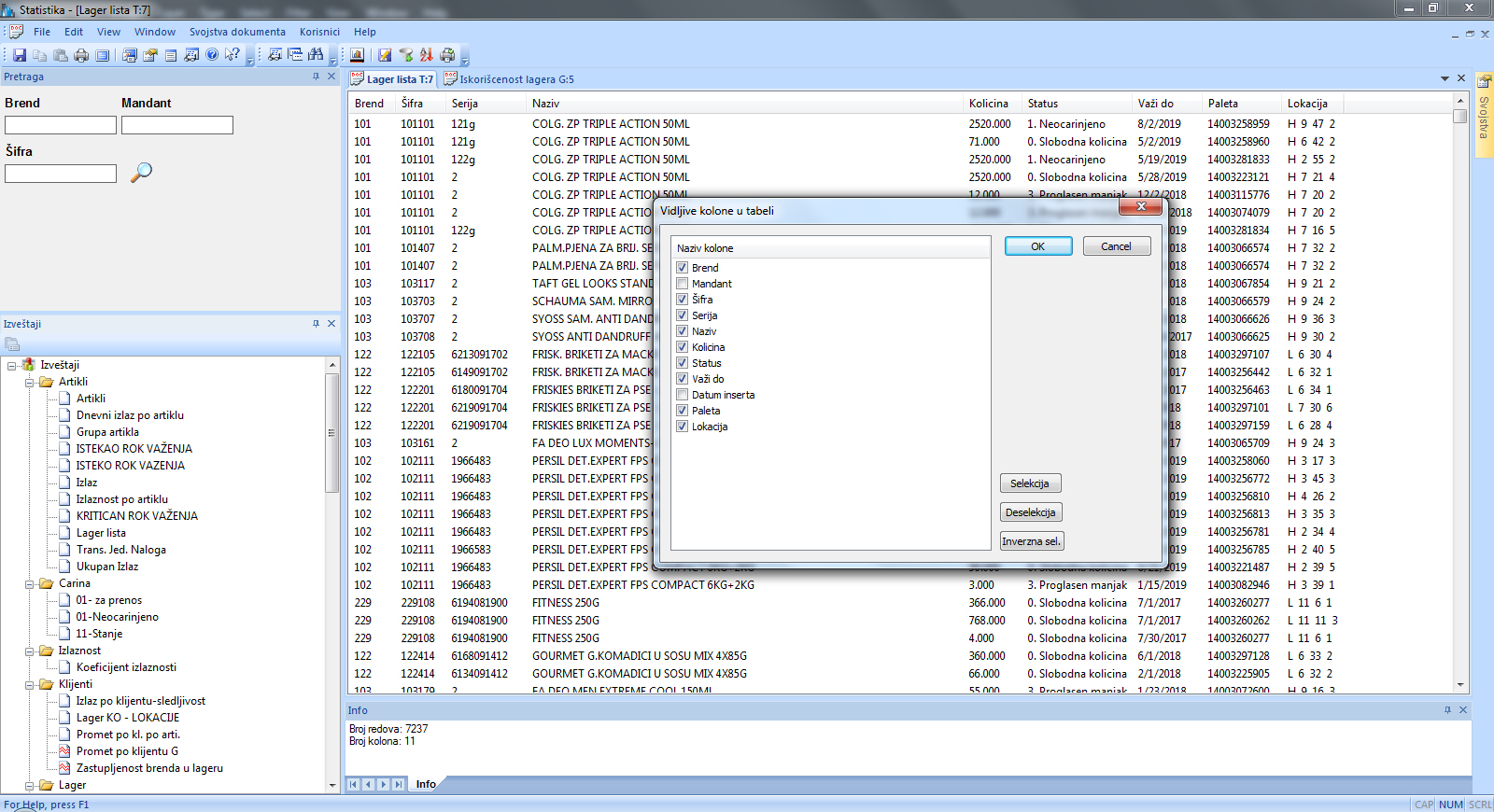

WMS Statistika

Application description

Statistika is an application for generating and monitoring reports related to the WMS system. The application is modular designed and fully adjusted to the conditions of the client.

It provides easy and quick reporting on client-side by connecting and comparing the fields in the database. Relational data connectivity in a variety of reports can be used to easily generate reports for items tractability, workers performance, the history of the order processing, storage capacity, stock lists, frequency of items, transport, and many others, as appropriate for the client. Each of the reports can be made as tabular presentation or as a graph.

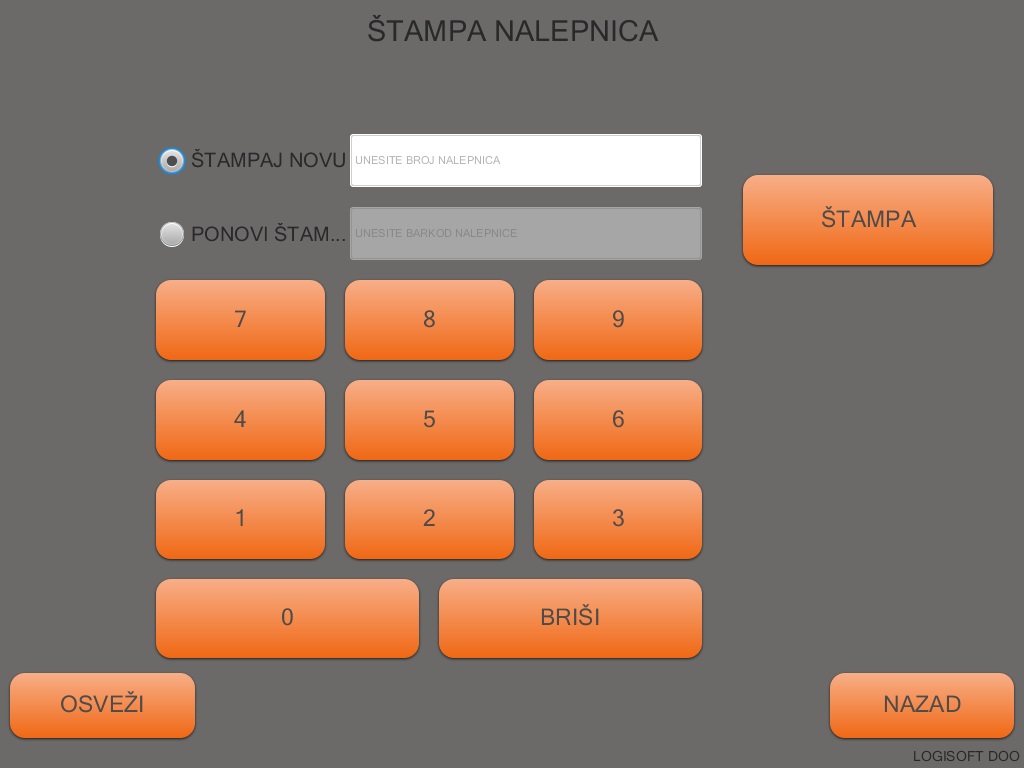

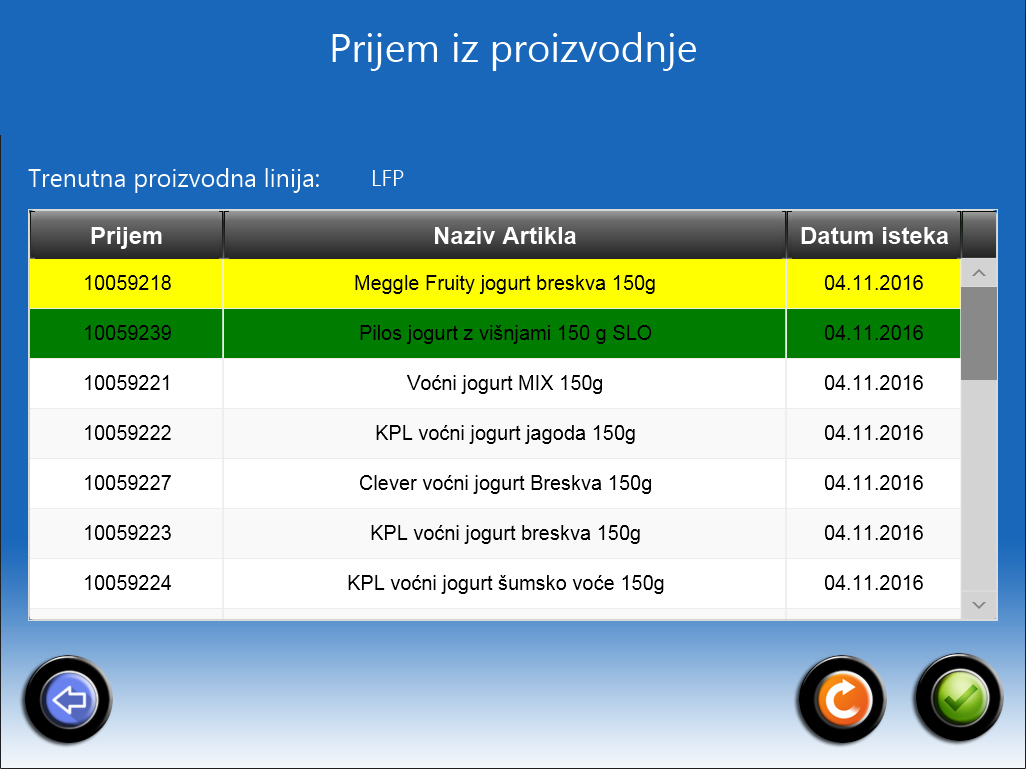

WMS LPView

Application description

LPView application allows easy control and recording of the entry of goods from manufacturing plants at the operational level of warehouse and production lines. The client application, which is developed on the JavaFX platform, enables easy and flexible configuration to meet the needs of the system and provides connectivity to external devices such as bar code scanners, scales for weighing items, PLC controllers, etc.